Injection moulding is a flexible process and can be applied to almost any merchandise. Although injection moulding may be the market normal for fabricating pieces for items, it is not without having its holdups. There are several standard limits to get thought about.

Here are some guidelines to follow when building your merchandise to guarantee high quality and durability:

Highest walls fullness. The wall structure fullness of your portion is straight proportionate to both complete supplies necessary to make your component along with the cooling down time needed. By reducing the maximum density of your wall structure of your respective aspect, you decrease both these elements, resulting in reduced routine time, hence lower generation costs. In case the wall of the part is way too thicker or perhaps is inconsistent, problems could be triggered connected with sinkage and warpage, resulting in rejects and pricey redesigns. Make sure your wall thickness is equaled for the functionality of your unit.

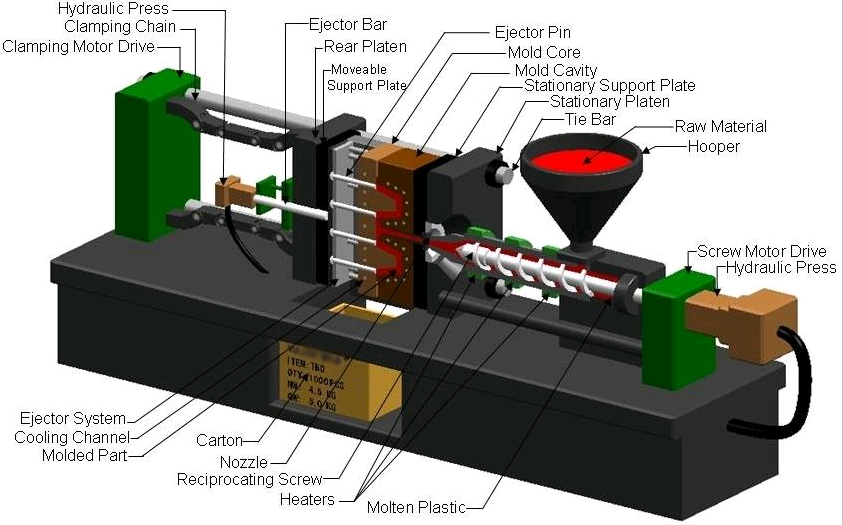

Corners. They could be a problem in a mould and may not necessarily come out flush. It can be extremely difficult to make plastic right into an excellent area, and the result can look untidy and amateurish, not to mention the strength of the component could possibly be jeopardized. Spherical all edges where possible to enhance aesthetics and durability. Implementing a draft. A draft is really a tiny position – typically one or two qualifications – put on the form in the face perpendicular on the parting range. This will allow for effortless removing of the piece from the mould. Not including a write within your design indicates the automated ejection method from the plastic injection moulding equipment will never work.

Ribs. Ribs are structural elements for your personal aspect, used for overall stability handle. These are slender wall protrusions that lengthen perpendicularly from the wall structure or aero plane. Adding ribs as an alternative to thicker surfaces will offer you better architectural help. Employers. Bosses are hollow, cylindrical protrusions typically included in a style for taking screws or any other mating components of your deign. Ensuring these are secured by possibly fixing those to a wall structure or including ribs will mean the bosses will always be direct and acknowledge the aspect it had been intended for without a difficulty. External undercuts. A protrusion or depression in the outside of your mildew – the cavity half – can cause problems when trying to individual pieces from the fungus. Adjust your parting series to support this. Inside undercuts or overcuts. Comparable to outside undercuts, these protrusions or depressions are within your fungus – about the key half. Change your parting line to fit this.